Off Season Operations Check Up

As the kids get ready to go back to school, the last of the beach trips wrap up and football once again takes over our weekends, there are a few steps that every company should keep their eye on. When a company takes a summer break or has a lull in the action, this is the best time for owners to take a breath and look at the operation side of their business. The sales department is using this time to assess their year end goals and tactics to get there. However, the operations side is just assumed they are ready. Therein lies the problem.

If you are like most companies that have a sales cycle throughout your year, there is usually a sigh of relief at the end of one season and a thought that there is plenty of time before it picks up again. This is the time to take a quick break and get right back at it from an operational standpoint. Believe it or not, in as little as 1-3 hours per week, you can take your lessons learned and turn them into better efficient processes for the future.

When I start to work with clients, they feel that taking the time to learn from mistakes and improve is too time consuming. How could they possibly get everyone that needs to be in the meeting together, there is just no time. This is the classic mistake. Kaizen (改善) is the Sino-Japanese word for “improvement”. In business, kaizen refers to activities that continually improve all functions and involves all employees from the CEO to the assembly line workers. Our industry tends to think these techniques are reserved for major corporations and multi-million dollar conglomerates. In fact, the smaller size of most of the companies in the industry makes this process even easier once started in the company. Consider these scenarios:

Eliminating extra runs to events

Most companies believe they have a foolproof operations process for their events. When they dig into the overall Event Lifecycle, companies learn more about their flaws. One client of mine gathered their operations team and asked a simple question to each of the 6 people at the table. “Tell me how you pack out an event?” The client was surprised to hear 6 different methods from the team. We worked with the team to simplify the process and even add in a double check from another teammate once equipment was loaded on the truck.

Learning and Improving

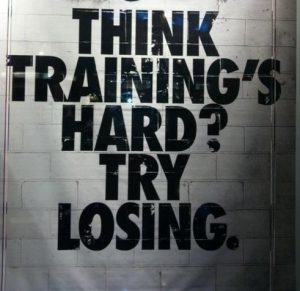

We all use the saying “learn from your mistakes” probably daily. How many of us actually take the time to add in the learning component? Over the years, at Picnic People in San Diego, we tried various methods of taking the mistakes and making those continuous improvements. At times we had the Operations Managers join the sales team for feedback, other times we held department head meetings to share feedback from all the departments, and we even tried bringing in the event supervisors to give us their version at monthly events. There is no secret sauce to solicit feedback, anyone that works for you will give it to you if you ask. The secret sauce is actually taking that feedback, discussing with the decision makers and implementing the changes to prevent the issue from happening again. Believe it or not, this should not take more than the initial meeting, maybe some follow up within 24-48 hours and then a couple hours to train the new process. Ask any successful company in the world why they stay on top, its because they are not afraid to make mistakes and have a plan to learn from them.

Document, Implement, Train…Repeat

When companies first start to implement a continuous improvement program and understand their Event Lifecycle, their success is measured by the degree that they have a pig headed stubborn attitude to not make previous mistakes again. Anyone can talk about what they should do to prevent repeating the past, the successful companies show their employees how to not repeat. Ask yourself if you have a single written procedure for one business process in your company. Good, now use that written documentation to train every new employee that comes in contact with the process so the process happens the same way every time. Imagine if you will that today’s employee is out sick in 3 days when the process needs to happen again. Will a co-worker be able to explain how and why the process needs to happen a certain way? The answer should always be “YES and here is a training piece to show you why and how we do it this way.”

These are just a few examples of thoughts that should be given to the operations side of the business whenever an owner has time to come up for air. Management teams should learn to embrace mistakes as support/training opportunities. One client of mine used to not let the management team leave the weekly meeting until they all decided on the new process, the documentation and who would do the training. One item a week might be the best start. Do you have 52 items on your business strategic plan list that you wish you could fix? Why not start with one and see how it goes. Feel free to share your thoughts or questions at f.christian@tayloredhs.com

See you on the dock!